The occurrence of nickel is quite rare in the world. The raw ores are mined from sulphides-, oxides- or in silicate form. The metallic ore is enriched through further processing and nickel is subsequently produced by electrolysis or direct reduction. Pure nickel wire, sheets or piping processed using this method is widely used in many industries. Nevertheless, nickel is used in its pure state for manufacturing nickel alloys and surface coating, with steelmakers using the largest quantity of it in order to alloy steels. Within this field the application of nickel-based welding fillers is important. These are used with materials operating under heavily corrosive and/or hot working conditions, like cryogenic liquid gas tanks, the cladding of water turbines and . Nickel is also used for manufacturing equipment with dissimilar joints. Use of nickel-based welding materials is based on their physical and metallurgical properties. Table 1. shows the physical properties of different alloys.

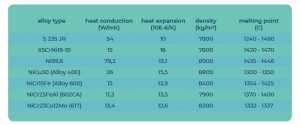

Table 1. Some basic physical properties of nickel alloys. (alloy type, heat conduction, heat expansion, density, melting point)

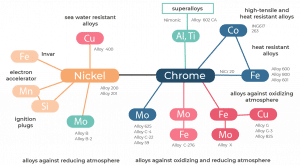

The main properties of different nickel alloys are: an austenitic structure, surface oxide layer, lack of allotropic transformation, and often also a precipitation-hardenable alloy. These properties specify the application fields of different alloys. Classification of nickel alloys according to alloying elements are shown in Figure 1.

Figure 1. Classification of nickel alloys according to their alloying elements

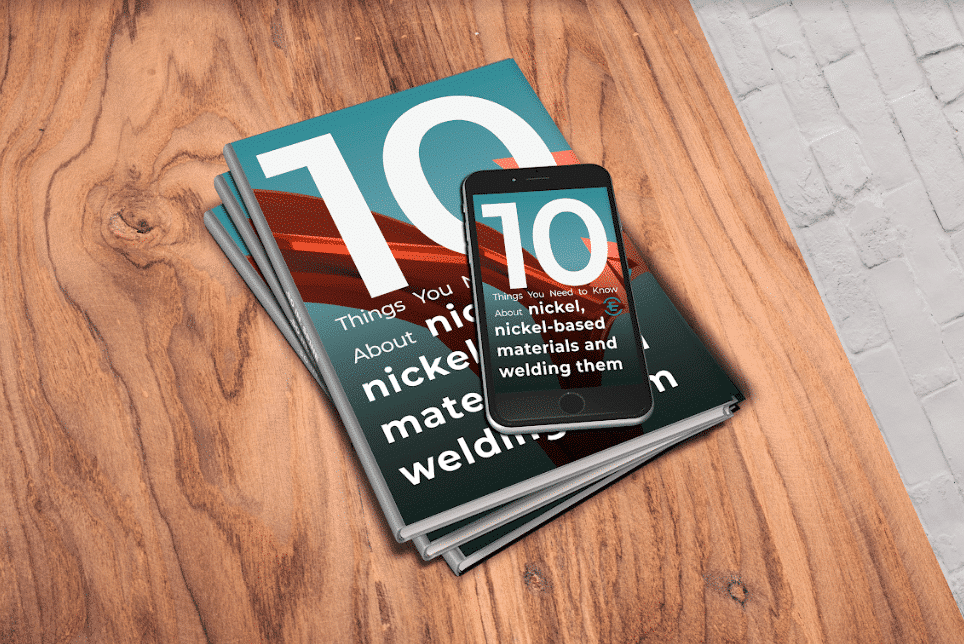

Among these alloying elements, copper is completely soluble in nickel, iron and chromium have a relatively good solubility, while molybdenum, cobalt, wolfram, vanadium, niobium and titanium are soluble to some extent in nickel as well. Welding filler manufacturers, including Böhler, have developed various kinds of welding materials for the different types of nickel alloy. Here we have introduced the fillers and examples of typical applications of them, in accordance with the classification of nickel alloys above. The data of the base materials and welding fillers mentioned in this article are demonstrated in Table 2.

Table 2. Data of typical nickel alloys and their welding fillers (number, nickel-based alloys/welding material, chemical composition, application, material number, EN name, ASTM name)